We blend cutting-edge technical expertise

with a robust portfolio of top-tier steel product

that combines innovation ad sustainability

Expertise that drives innovation

Our deep technical knowledge enhances product performance and production efficiency in automotive applications.

The one-stop shop for automotive producers

From flat rolled sheets to customized tubes, our extensive product range meets every automotive need whit precision and quality.

Committed to a sustainable future

Our environmentally-conscious approach ensures sustainable production processes that support the eco-friendly goals of the automotive industry.

Explore all our product applications

Expansion joint for exhaust system

Parts made of both austenitic and ferritic alloy in various thicknesses after annealing

Produced by

Arinox

Disc brake calipers

Parts made from rolled austenitic 301 hardened steel, thicknesses 0.4 - 0.5 mm

Produced by

Arinox

Ball bearings

Parts made of ferritic alloy 430 steel, annealed and with thickness > 0.5 mm

Produced by

Arinox

Engine gaskets

Parts made of austenitic 301 alloy at thicknesses of 0.20 or 0.25 mm. Condition: work-hardened by rolling

Produced by

Arinox

Engine heat shields

Parts made from both austenitic and ferritic alloy strip, at thicknesses > 0.4 mm. Annealed condition

Produced by

Arinox

Trim strips

Its aesthetic appearance makes stainless the ideal material for all decorative components (moldings, window frames, heel stops).

Produced by

Arvedi AST

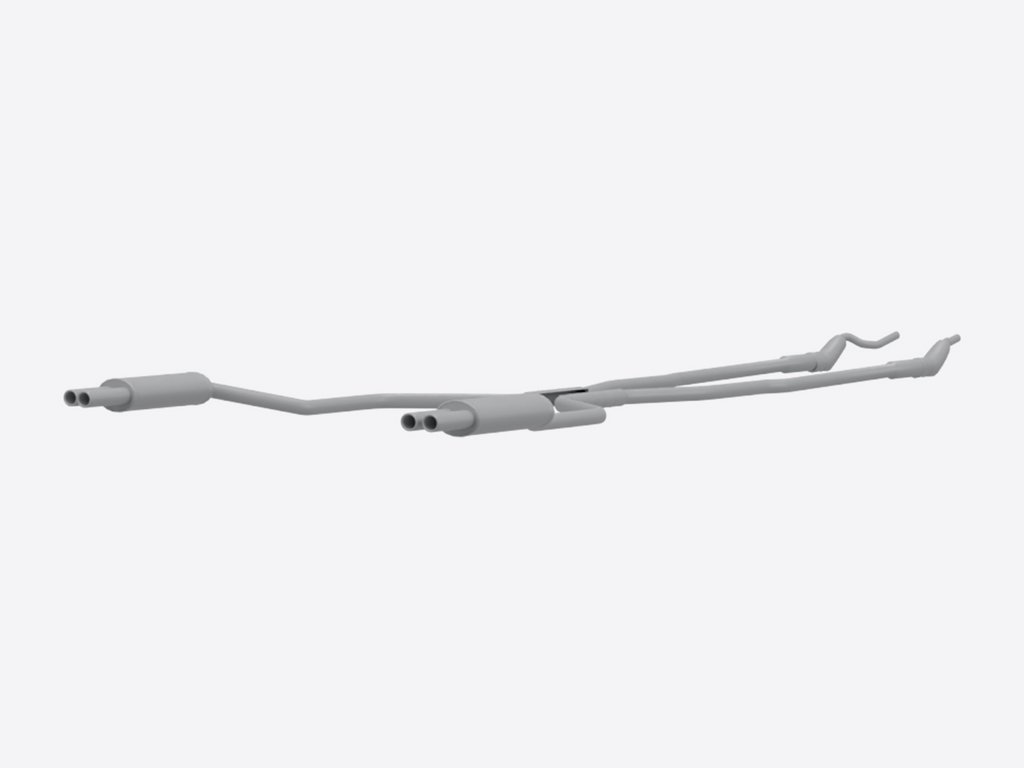

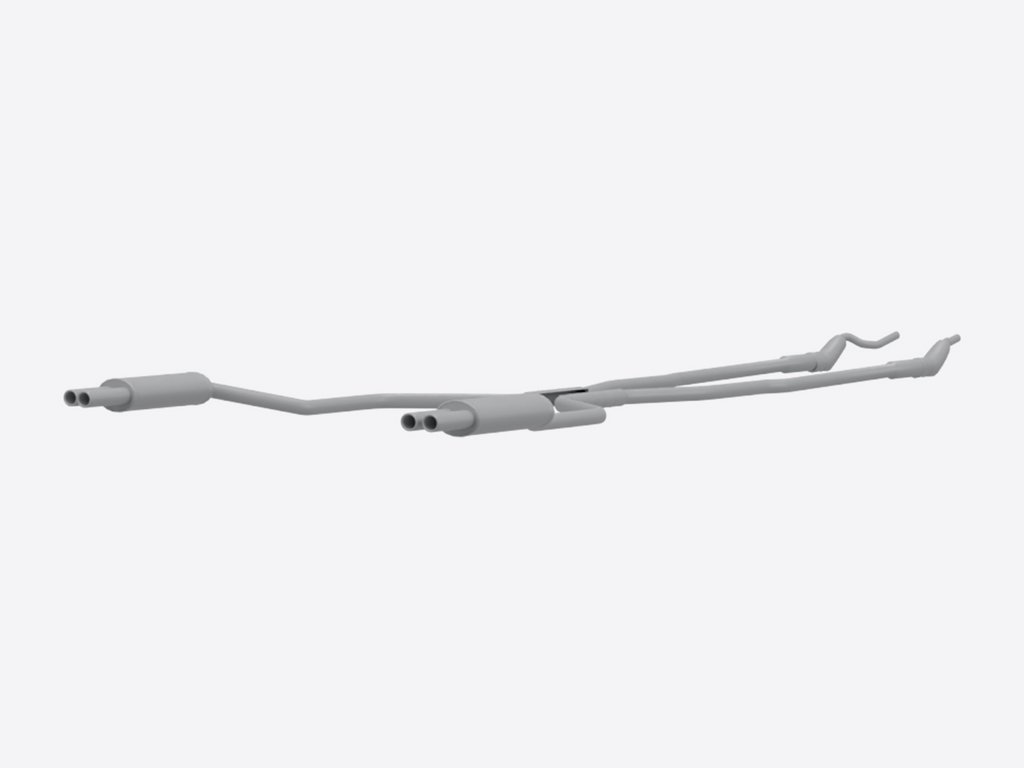

Exhaust manifold

Stainless steel, due to its superior mechanical and physical properties, including heat resistance and corrosion resistance, is used in the automotive industry for exhaust systems from manifold to muffler.

Produced by

Arvedi AST

Catalytic / Catalyst System

Stainless steel specifications: wet corrosion resistance, resistance to pitting, resistance to corrosion in chlorinated environments, resistance to thermal oxidation.

Produced by

Arvedi AST

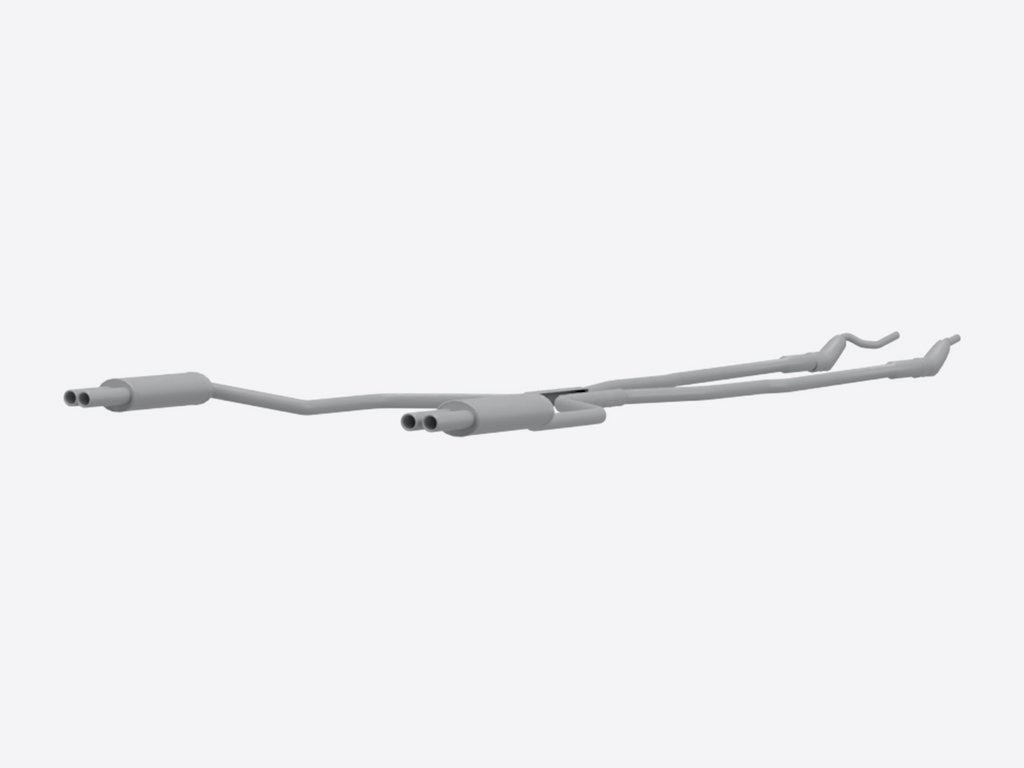

Muffler

Stainless steel, due to its superior mechanical and physical properties, including heat resistance and corrosion resistance, is used in the automotive industry for exhaust systems from manifold to muffler.

Produced by

Arvedi AST

Exhaust Manifold

They are components of a motor's exhaust system, used to collect and channel the exhaust gases produced by the combustion inside the engine cylinders towards the exhaust system, which expels them through the exhaust pipe.

(T>900°; EN 1.4828, EN 1.4541, EN 1.4509, AST 441M, EN 1.4845)

Produced by

Tubificio Terni

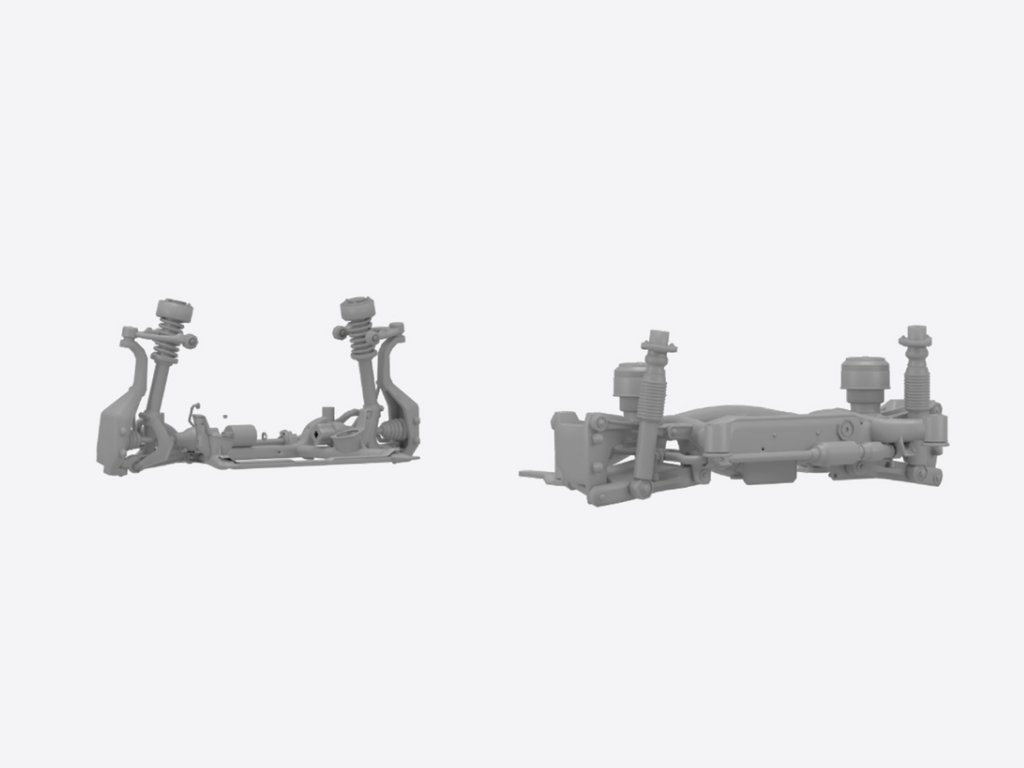

Shock absorber

Steel and material supply condition in accordance with EN 10305-2. The tube is supplied cut to length according to the finished component drawing.

Produced by

Metalfer

Gas spring (filled strut)

Steel and material supply condition in accordance with EN 10305-2.

Produced by

Metalfer

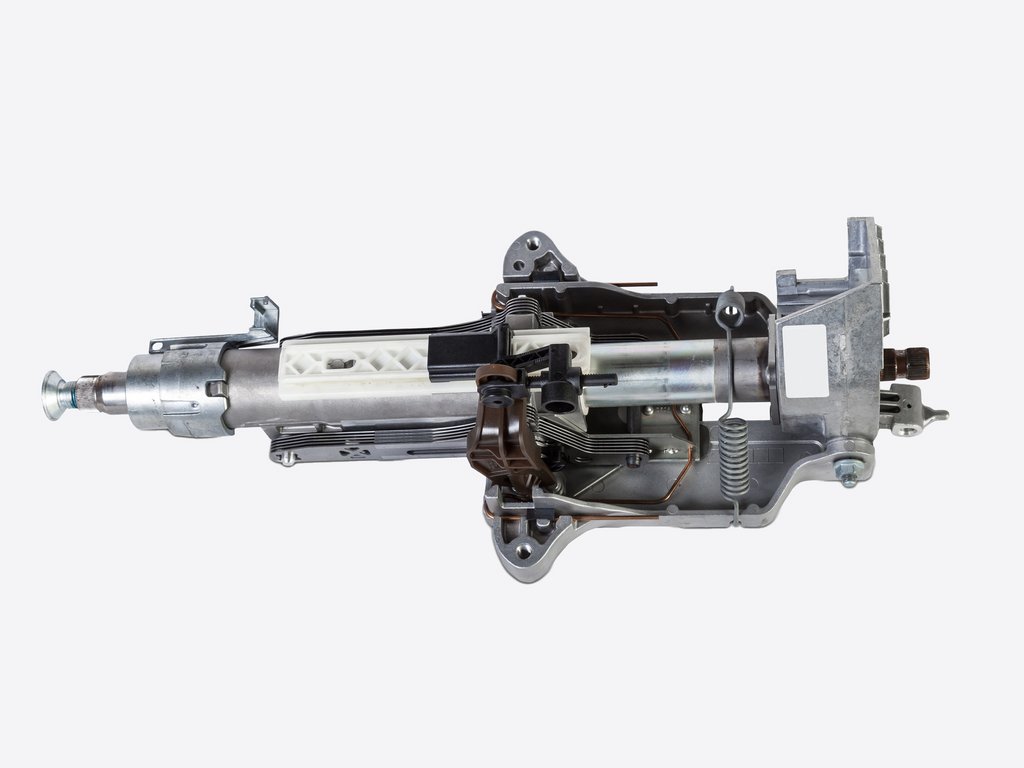

Steering column

Steel and material supply condition in accordance with EN 10305-2. The tube is supplied cut to length according to the finished component drawing.

Produced by

Metalfer

Camshaft

Steel and material supply condition in accordance with EN 10305-2. The tube is supplied cut to length according to the finished component drawing.

Produced by

Metalfer

Driveshaft

Steel and material supply condition in accordance with EN 10305-2. The tube is supplied cut to length according to the finished component drawing.

Produced by

Metalfer

Tubular torsion bars

Steel and material supply condition in accordance with EN 10305-2.

Produced by

Metalfer

Axle shaft

Steel and material supply condition in accordance with EN 10305-2.

Produced by

Metalfer

Silent blocks

Steel and material supply condition in accordance with EN 10305-2. The tube is supplied cut to length according to the finished component drawing.

Produced by

Metalfer

Side impact protection bar

Steel and material supply condition in accordance with EN 10305-2.

Produced by

Metalfer

Belt tensioner

Steel and material supply condition in accordance with EN 10305-2.

Produced by

Metalfer

Rear axle parts

Tubes are bent, deformed, and machined. The resulting parts are usually assembled by welding to make up the rear frame.

Produced by

Arvedi Tubi Acciaio

Transmission cardan shaft

Used in rear-wheel drive and 4x4 vehicles. The tube is made with special equipment to ensure peculiar dimensional tolerances; it is cut to length, and universal joints are assembled at the ends of the part.

Produced by

Arvedi Tubi Acciaio

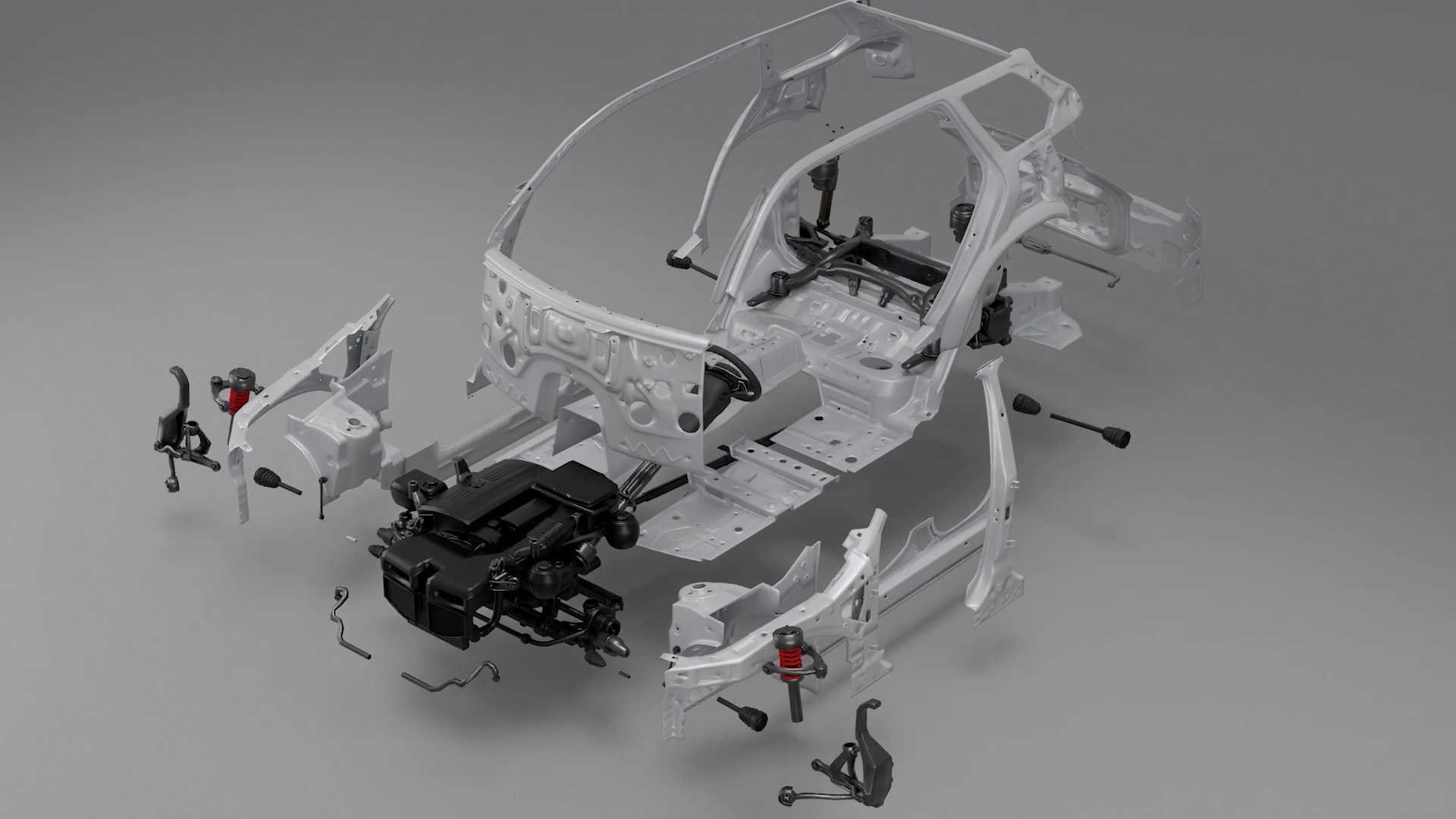

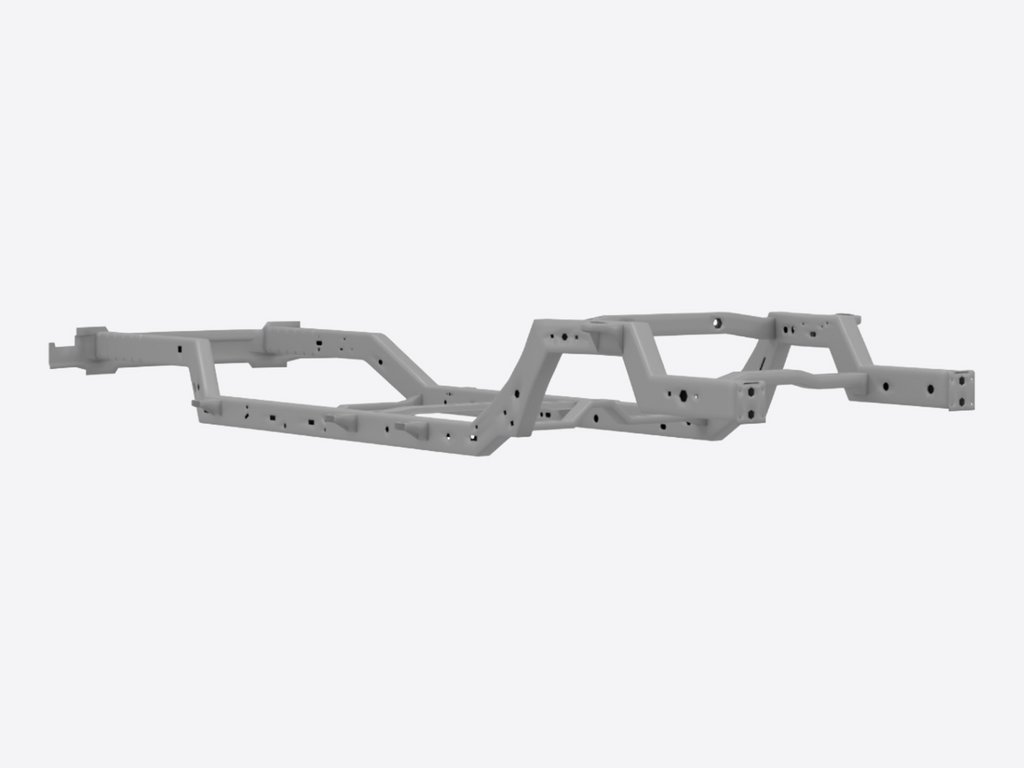

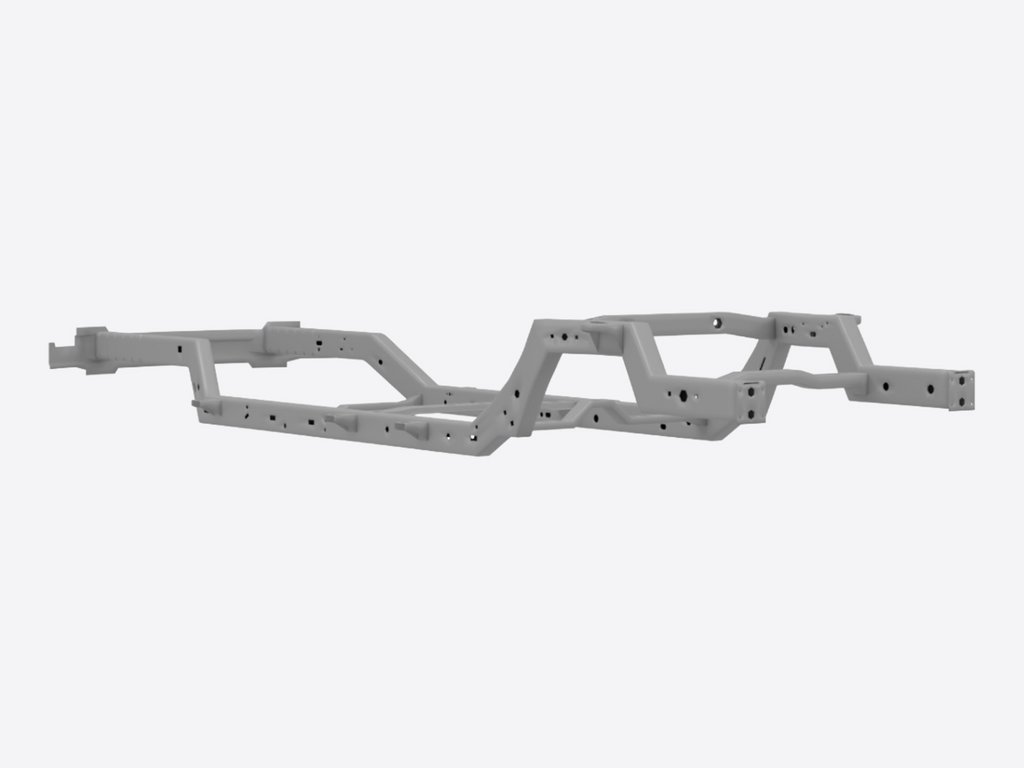

Chassis Parts

Tubes are cut, deformed, and machined. The resulting parts are usually assembled by welding to make up the load-bearing chassis, which is used on cars and trucks for off-road or extreme use. In these cases the bodywork is not load-bearing and rests on the chassis. Many of its components are made from tube.

Produced by

Arvedi Tubi Acciaio

Front (engine) subframe

The application is developed from a tube made by hydroforming, allowing complex and articulated shapes that would otherwise be impossible to produce by bending and/or pressing alone.

Produced by

Arvedi Tubi Acciaio

Hood and trunck locks

Steel supplied cut to size, starting with coils from Acciaieria Arvedi.

Produced by

CSI

Fuel tank

Steel supplied cut to size, starting with coils from Acciaieria Arvedi.

Produced by

CSI

Dashboard internal panel

Steel supplied cut to size, starting with coils from Acciaieria Arvedi.

Produced by

CSI

Seating support

Steel supplied cut to size, starting with coils from Acciaieria Arvedi.

Produced by

CSI

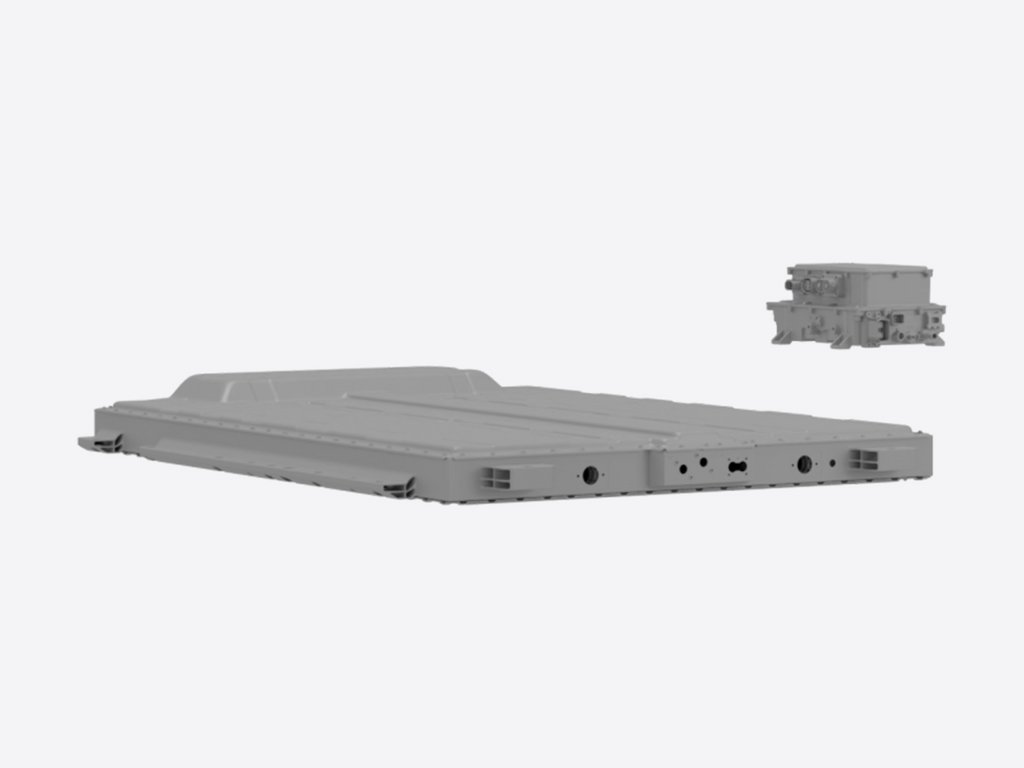

Battery box

Steel supplied cut to size, starting with coils from Acciaieria Arvedi.

Produced by

CSI

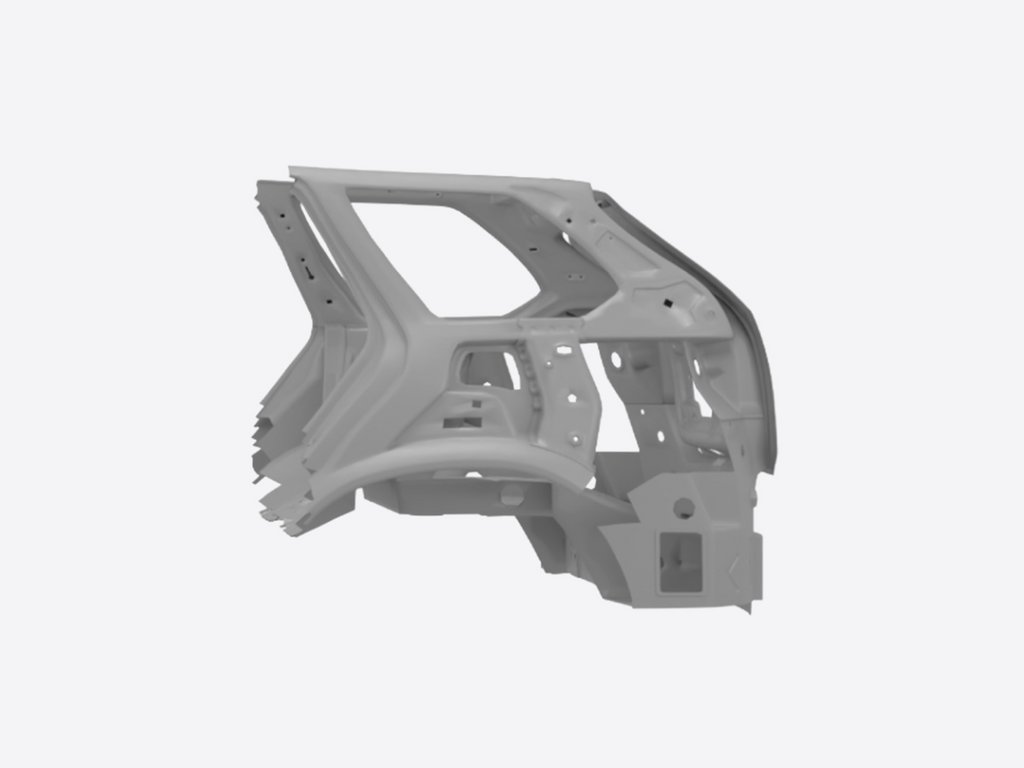

Door pillar

Steel supplied cut to size, starting with coils from Acciaieria Arvedi.

Produced by

CSI

Bracket

Steel supplied cut to size, starting with coils from Acciaieria Arvedi.

Produced by

CSI

Stainless engine plates for Fuel Cells

The strip is generally cold rolled down to a thickness of 0,10 mm or even 0,075 mm, into a bright annealed state. This is necessary to mold the plate surface for creating a channel of different geometry, necessary to enable the deep diffusion of hydrogen and consequently the release of electrons that generate the electricity for the vehicle engines. The channel plate enables also the combination of hydrogen with oxygen in the air creating as only exhaust product, simply water.

Produced by

Arinox

Transmission cardan shaft

Used in rear-wheel drive and 4x4 vehicles. The tube is made with special equipment to ensure peculiar dimensional tolerances; it is cut to length, and universal joints are assembled at the ends of the part.

Produced by

Metalfer

Catalytic converter

It is a component of a vehicle's exhaust system that serves to reduce the emissions of harmful gases produced by the engine's combustion, converting them into substances that are less harmful to the environment.

(700°<T<900°; EN 1.4541; EN 1.4301; EN 1.4509; EN 1.4513)

Produced by

Tubificio Terni

Connecting Pipe

These pipes are used to connect the various components of the exhaust system, such as the exhaust manifold, the catalytic converter, and the muffler, allowing the flow of exhaust gases.

(500°<T<600°; EN 1.4509; EN 1.4510; EN 1.4512)

Produced by

Tubificio Terni

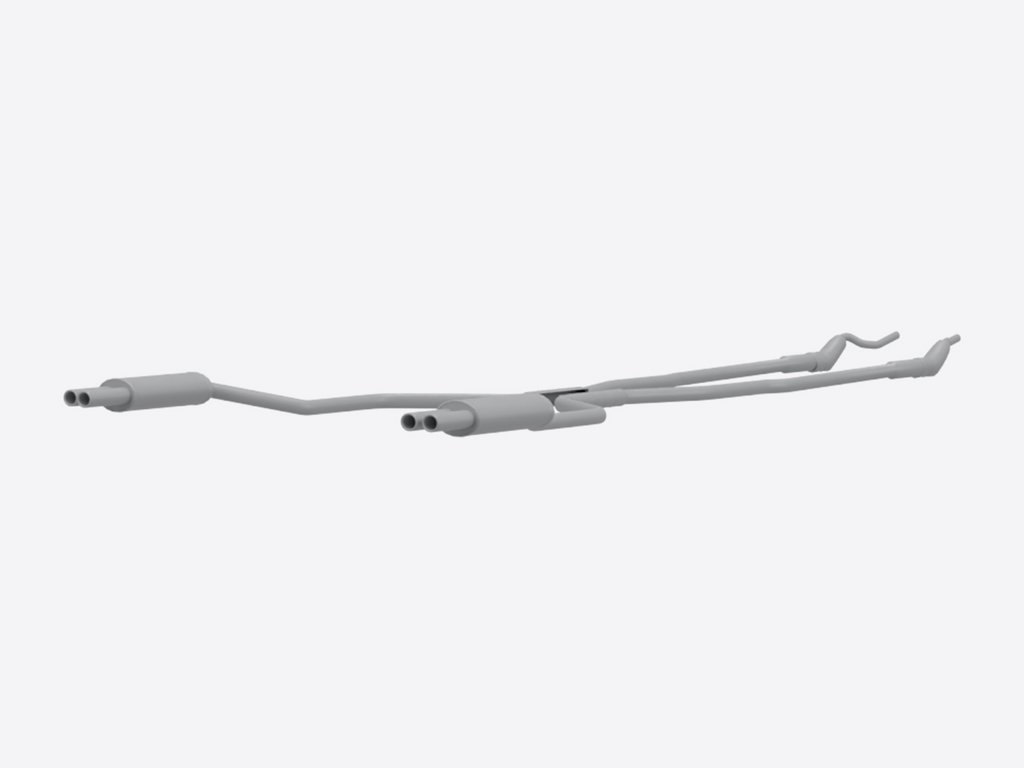

Muffler

Stainless steel, due to its superior mechanical and physical properties, including heat resistance and corrosion resistance, is used in the automotive industry for exhaust systems from manifold to muffler.

(T < 400° C; EN 1.4512; EN 1.4301; EN 1.4513; EN 1.4509)

Produced by

Tubificio Terni

Tail pipe

They are the final ends of a vehicle's exhaust pipes. They are located at the end of the exhaust system and serve to direct the exhaust gases outside the vehicle.

(T<400°; EN 1.4513; EN 1.4301; EN 1.4512, EN 1.4401)

Produced by

Tubificio Terni

Rim Wheel

Microalloyed pickled steel components with tight thickness tolerances

Produced by

Acciaieria Arvedi

Product brand

Front rails

Multiphase dual phase steel for high ductility and energy absorption

Produced by

Acciaieria Arvedi

Product brand

Central tunnel reinforcement

High-strength microalloyed steel component

Produced by

Acciaieria Arvedi

Product brand

Lateral longitudinal reinforcement

High-strength microalloyed steel component

Produced by

Acciaieria Arvedi

Product brand

Rear longitudinal reinforcement

High-strength microalloyed steel component

Produced by

Acciaieria Arvedi

Product brand

Front longitudinal reinforcement

High-strength microalloyed steel component

Produced by

Acciaieria Arvedi

Product brand

Rear rails

High-strength microalloyed steel component

Produced by

Acciaieria Arvedi

Product brand

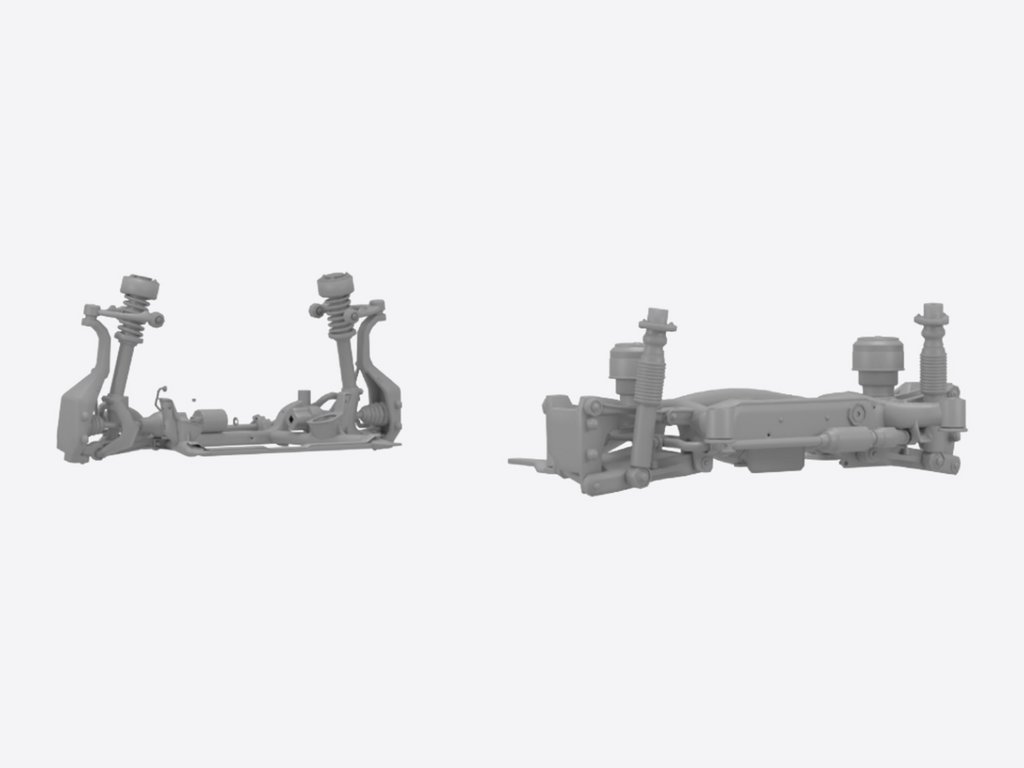

Front and rear control arms

Ferritic bainitic multiphase steel components

Produced by

Acciaieria Arvedi

Product brand

Rear chassis

Microalloy pickled steel components

Produced by

Acciaieria Arvedi

Product brand

Seat rails

Microalloyed pickled steel components with tight thickness tolerances

Produced by

Acciaieria Arvedi

Product brand

Safety belts

Microalloyed pickled steel components with tight thickness tolerances

Produced by

Acciaieria Arvedi

Product brand

Backing plates

Microalloyed pickled steel components with high stamping ability and tight dimensional tolerances

Produced by

Acciaieria Arvedi

Product brand

Gearbox

Low carbon microalloyed and structural pickled steel components

Produced by

Acciaieria Arvedi

Product brand

Disclaimer: our steel is utilized in the production of specific applications; therefore, we are not the manufacturers of the final parts.